Understanding the Evolution of Personalized Titanium Mesh Solutions

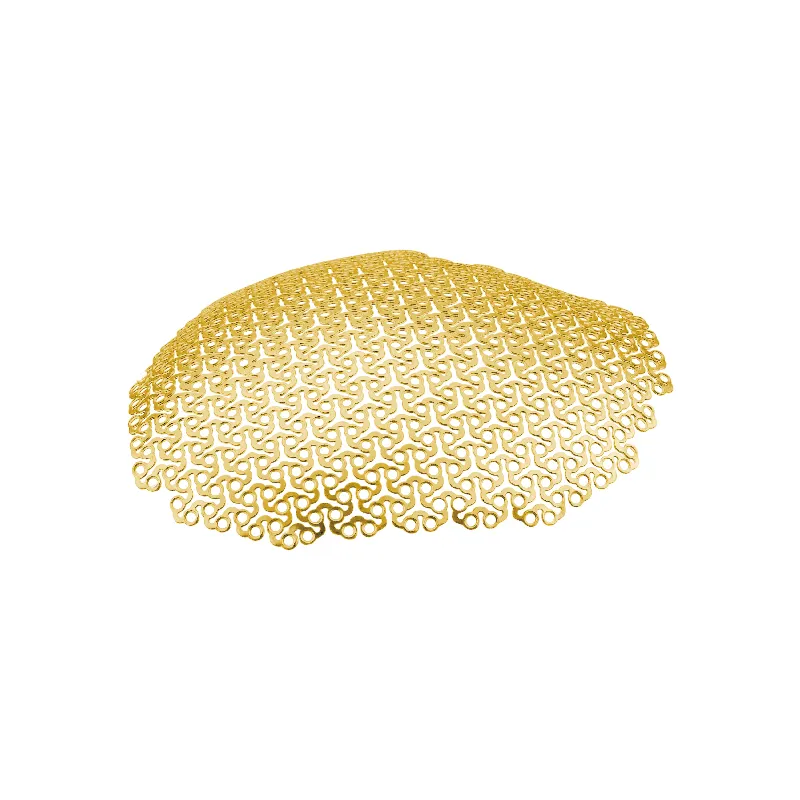

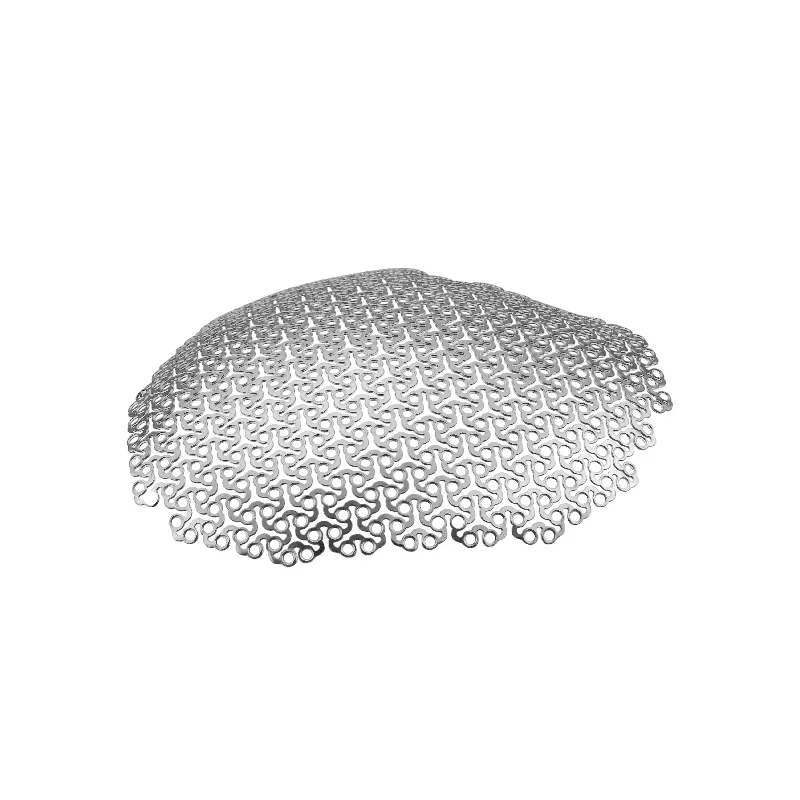

The medical industry has witnessed remarkable advancements in the field of patient-specific implants, with titanium mesh customization leading the way in revolutionary treatment approaches. This sophisticated process combines cutting-edge technology with precision engineering to create implants that perfectly match individual patient anatomy. The transformation from standard, off-the-shelf solutions to personalized titanium mesh has dramatically improved surgical outcomes and patient satisfaction.

Today's titanium mesh customization integrates advanced imaging techniques, computer-aided design, and state-of-the-art manufacturing processes to produce implants that address unique anatomical requirements. This personalized approach has become particularly crucial in reconstructive surgery, cranial procedures, and orthopedic applications where anatomical accuracy is paramount for successful outcomes.

Advanced Technology in Titanium Mesh Design

3D Imaging and Digital Planning

The journey of titanium mesh customization begins with precise patient imaging. Advanced CT and MRI scans create detailed three-dimensional representations of the target anatomy. These high-resolution images serve as the foundation for digital planning, allowing surgeons and engineers to collaborate effectively in designing the perfect implant solution.

Sophisticated software platforms process these images, enabling medical professionals to manipulate and analyze the data from multiple angles. This comprehensive visualization helps identify crucial anatomical landmarks and ensure optimal implant fit, while considering factors such as tissue thickness and surrounding structures.

Computer-Aided Design and Modeling

Once the imaging data is processed, specialized CAD software transforms the digital information into detailed implant designs. Engineers can adjust various parameters including mesh density, thickness, and structural patterns to meet specific mechanical requirements. This precise control allows for the creation of implants that balance strength, flexibility, and biocompatibility.

The modeling phase also incorporates stress analysis simulations to verify the implant's structural integrity under various physiological loads. This crucial step ensures the customized titanium mesh will perform reliably in real-world conditions while maintaining patient comfort and safety.

Manufacturing Processes and Quality Control

Additive Manufacturing Excellence

The physical creation of customized titanium mesh typically employs advanced additive manufacturing techniques, particularly selective laser melting (SLM) or electron beam melting (EBM). These sophisticated processes build the implant layer by layer, following the exact specifications from the digital design. The precision of these manufacturing methods ensures exceptional accuracy in reproducing complex geometries and internal structures.

Modern 3D printing technologies allow for the incorporation of specific surface textures and porosity levels that promote tissue integration and healing. This level of manufacturing control helps optimize the biological response to the implant while maintaining its mechanical properties.

Quality Assurance Protocols

Rigorous quality control measures govern every step of the titanium mesh customization process. Each implant undergoes detailed inspection using high-precision measurement tools and advanced imaging systems to verify dimensional accuracy. Surface quality, material consistency, and structural integrity are thoroughly evaluated to ensure compliance with medical device regulations.

Documentation and traceability systems maintain records of all manufacturing parameters, material certifications, and quality control results. This comprehensive approach to quality assurance provides confidence in the safety and reliability of each customized implant.

Clinical Applications and Benefits

Surgical Planning Advantages

Patient-specific titanium mesh offers significant advantages in surgical planning and execution. Surgeons can virtually plan procedures using accurate 3D models of the customized implant, reducing operating time and improving precision. This preoperative preparation helps anticipate potential challenges and optimize surgical approaches.

The availability of exact anatomical matches eliminates the need for intraoperative adjustments, leading to more predictable outcomes and reduced complications. This efficiency translates to shorter recovery periods and improved patient experiences.

Long-term Patient Outcomes

Clinical studies consistently demonstrate superior results with customized titanium mesh compared to standard implants. The precise fit promotes better tissue integration and reduces the risk of complications such as implant migration or exposure. Patients typically report higher satisfaction levels due to improved aesthetic results and functional outcomes.

The durability and stability of customized titanium mesh implants contribute to long-term success rates. The combination of optimal fit, appropriate mechanical properties, and biocompatibility supports sustained positive results across various clinical applications.

Future Developments and Innovations

Emerging Technologies

The field of titanium mesh customization continues to evolve with emerging technologies. Advanced materials science is exploring new titanium alloys and surface treatments that could further enhance biological integration and healing responses. Artificial intelligence and machine learning are being integrated into the design process to optimize implant characteristics based on vast databases of clinical outcomes.

Research into smart implant technologies may soon enable the incorporation of sensors and monitoring capabilities within customized titanium mesh. These innovations could provide real-time data on healing progress and implant performance, leading to more informed patient care decisions.

Expanding Applications

The success of titanium mesh customization is driving expansion into new medical applications. Researchers are exploring novel uses in spine surgery, joint reconstruction, and facial reconstruction. The technology's versatility and proven benefits are opening possibilities for addressing increasingly complex medical challenges.

Integration with other emerging medical technologies, such as bioprinting and tissue engineering, may create hybrid solutions that combine the structural advantages of titanium mesh with enhanced biological functionality.

Frequently Asked Questions

What makes titanium the preferred material for customized medical implants?

Titanium is chosen for its exceptional biocompatibility, high strength-to-weight ratio, and corrosion resistance. Its ability to osseointegrate with bone tissue while maintaining structural integrity makes it ideal for long-term medical implants. Additionally, titanium's compatibility with modern manufacturing processes enables precise customization.

How long does the customization process typically take?

The complete process of titanium mesh customization usually takes between 2-4 weeks, depending on the complexity of the case. This timeline includes initial imaging, design planning, manufacturing, quality control, and sterilization. Emergency cases can be expedited through streamlined protocols when necessary.

What factors influence the cost of customized titanium mesh implants?

The cost varies based on several factors, including implant size, complexity of design, manufacturing requirements, and quality control measures. While customized solutions may have higher initial costs than standard implants, they often provide better value through improved outcomes, reduced complications, and decreased revision surgery rates.

EN

EN

FR

FR

ES

ES

AR

AR