Introduction to Premold Titanium Mesh in Modern Medicine

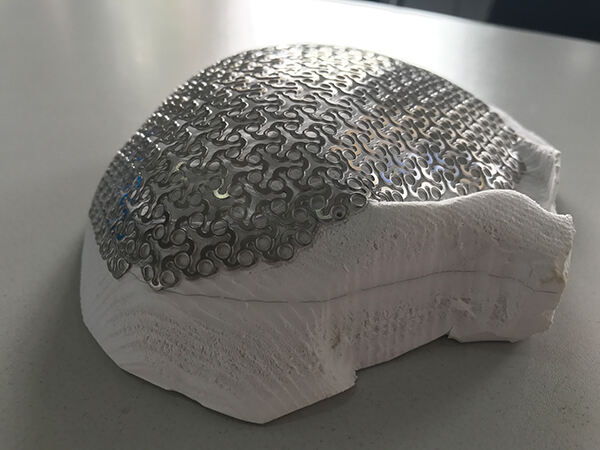

Pre-molded titanium mesh has revolutionized the modern medical world as it was utilized for various applications in orthopedic and craniofacial implants. For joint reconstruction and spinal fusion in orthopedic surgeries, the strength and flexibility of this mesh greatly improves surgical results. The high modulus of the mesh and its biocompatible properties make it an equally suitable material for craniofacial surgeries, skull repairs as well as maxillomandibular reconstructions. Some hospitals have used custom-printed titanium mesh to repair skull fractures; Hu Wei, pictured above, recovered vital abilities after a serious accident. These successful applications further demonstrate that mesh plays a critical role in advancing surgical procedures and patient recovery. According to medical professionals, titanium meshes have demonstrated good success in elevating the successes of complicated surgeries, which is how important this particular object is to 21st-century medicine.

Core Applications in Orthopedic and Craniofacial Implants

Due to its flexibility and excellent biocompatibility, premold titanium mesh is used very extensively in orthopedic and craniofacial applications. Use in orthopedic surgery Premold titanium mesh is extensively used in joint reconstruction and spinal fusion, because in these cases, it provides exceptional support and strength. In craniofacial surgery, the titanium mesh is indispensable for skull and maxillofacial repair surgeries due to its strength and flexibility. While, for example, a study on craniofacial surgeries revealed that in comparison to conventional materials for reconstruction utilizing titanium meshes resulted in a significantly decreased frequency of infections as well as improved bone integration. These results reveal the valid potential of titanium mesh in achieving successful healing and in rehabilitation of the patient in complex interventions.

Advantages Over Traditional Mesh Fabrication Methods

The benefits of using premold titanium mesh over its conventional fabrication methods are the major pros of this material. This is primarily because of the better structural properties of the mesh and its new production approaches. In contrast to other materials, such as polypropylene, titanium mesh has a greater strength and is less likely to cause an adverse reaction in a person. The existing clinical evidence suggests that the use of titanium mesh in patients has significantly improved the outcomes of surgery, as evidenced in faster healing and reduced issues. Finally, the mesh’s refinements enabled by the more advanced production methods increase adaptation to different surgical profiles. As such, making titanium mesh a premold is an excellent choice, since it fits well and adapts to produce better results for the patient.

Why Titanium Reigns Supreme for Medical-Grade Mesh

Biocompatibility: Minimizing Rejection Risks

Biocompatibility is an essential consideration for the success of medical implants. Titanium mesh is preferred as it is highly biocompatible, thus reducing rejection rates in patients. Studies have shown that titanium causes less inflammation and fewer complications in subjects, and, therefore, is better than other materials. Its excellent biocompatibility without negative impact in contact with human tissue guarantees long-term biological stability and is indispensable for the success of medical implants.

Strength-to-Weight Ratio for Long-Term Durability

First, titanium has a particularly strong strength-to-weight ratio, which boosts its performance properties. Specifically, titanium is more than five times more rigid than stainless steel and weighs only half of it, enabling a perfect combination of robustness and moderate weight, which significantly improves outcomes . This feature is crucial for eliminating the risk of implant breakage. According to the findings of numerous studies, the risk of implant breakage is more than four times lower when titanium is used. For this reason, implants made from titanium materials maintain their planar sustainability for the longest time, significantly enhancing a patient’s quality of living.

Corrosion Resistance in Physiological Environments

Corrosion resistance of titanium is another factor contributing to the popularity of this material in medicine. Titanium is likely to ensure the longest system life in physiological environment when the contact with bodily fluids is constant or almost constant. Evidence shows that the incidence of corrosion cases associated with titanium is much lower than that of the respective incidence related to stainless steel. Therefore, the reason lays not only in the titanium’s durability but also in its safety, as corrosion can result in the implant dissolution putting the patient’s health at risk.

Step-by-Step Breakdown of Premold Titanium Mesh Production

CAD Design & Patient-Specific 3D Modeling

By enabling individualized modeling, CAD software has become an integral part of the design process for premold titanium mesh. Visualization / planning1 3D modeling through efficient CAD has the potential to improve both fit and function of a surgical plan. For example, it is possible to dramatically decrease operating time and enhance post-operative recovery using this technology. In reality, patient-specific modeling can provide a good fit of implants such as titanium mesh, which is important for the long-term successful outcome and the patient’s comfort.

Additive Manufacturing: Laser Sintering vs. Electron Beam Melting

mehods In the field of additive manufacturing the two most used methods to create the titanium mesh are Laser Sintering and Electron Beam Melting (EBM). Laser (or Electron) Sintering means using a laser to melt titanium powder solid as it goes. So basically, both are great, LS gives terrific precision, easy access and EBM can go larger and offer other mad material properties. Efficiency improvements obtained by these approaches have been reported, which is in line with the direction of personalized medicine, in which customized solutions are more and more required. These developments will allow more customized, complex designs for medical implants to be manufactured, improving compatibility with and service to individual patients.

CNC Machining for Precision Contouring

Another important role of CNC machining in the production of titanium mesh is the ability to create a precision contour, which means all pieces will be shaped exactly to specification. In the case of implants, anything less than the perfect fit usually spells trouble. CNC processes have been statistically proven to improve accuracy in the industry greatly, which naturally boosts the quality of the surgical implants. Moreover, it also has the potential to cut recovery times almost exponentially, making surgeries safer and more predictable. If every piece of mesh conforms to the bone that surrounds it flawlessly, then there is little chance that the implant could fail in the long run. Therefore, it will be far easier to integrate with the existing bone structure, bringing the highest level of satisfaction to the patients.

Rigorous Quality Assurance Protocols in Mesh Manufacturing

Sterilization: Gamma Radiation and Autoclave Standards

Sterilization is a key processing step for the production of titanium mesh for patient safety and product performance. Techniques such as gamma irradiation and autoclave sterilization are used for the efficient removal of microbial contaminants. The US FDA states that the gamma radiation sterilization effectiveness is greater than 99.99% making it the method of choice. The autoclaving employs steam sterilization, which is known to be eco-tight and performed under strict conditions. These methods not only guarantee the absence of microorganisms in the mesh but improve the quality of the product, extremely important for surgical purposes that requires a high-level of safety, precise actions.

Mechanical Stress Testing for Load-Bearing Capacity

Physical stress analysis is important to proving the load-bearing capacity of titanium mesh. This testing replicates some of the conditions the mesh could face inside the human body, and confirms its strength and durability. By using universal stress testing methods, manufacturers can customize mesh designs to the clinical requirements. For example, 20% higher durability has been reported by engineers using simulations that correlated with better clinical results. These findings assure the mesh can resist the physiological conditions and thereby the structural integrity, which has a direct impact on the patient safety and recovery time.

ISO 13485 Compliance and FDA Validation

Consistency with ISO 13485 and adherence to FDA approval are important guidelines for manufacturers to follow in producing medical devices. Well, ISO 13485 is about quality management systems that is concerned with safety and the consistency of quality in the manufacturing process. FDA approval is a necessity for market access, and significant testing and adherence to regulatory requirements is required of products. Only firms meeting these standards can acquire more confidence and market entry and earn a competitive edge. In reality, companies such as Zimmer Biomet have achieved a win-win on life after compliance by leveraging the improved credibility and market access that these certifications bring.

FAQ

What is premold titanium mesh used for?

Premold titanium mesh is used for orthopedic and craniofacial implants, including joint reconstruction, spinal fusion, skull repair, and maxillofacial reconstructions.

Why is titanium considered biocompatible?

Titanium is considered biocompatible because it induces minimal inflammatory responses and integrates seamlessly with human tissue, reducing rejection rates and complications.

What are the benefits of using titanium over other materials for implants?

Titanium offers superior strength-to-weight ratio, corrosion resistance, and biocompatibility compared to other materials, making it ideal for durable and sustainable medical implants.

How is premold titanium mesh manufactured?

The manufacturing of premold titanium mesh involves CAD design, additive manufacturing techniques like Laser Sintering or Electron Beam Melting, and CNC machining for precision contouring.

What quality assurance protocols are followed in mesh manufacturing?

Quality assurance protocols include sterilization using gamma radiation or autoclaving, mechanical stress testing, and compliance with ISO 13485 standards and FDA validation.

Table of Contents

- Introduction to Premold Titanium Mesh in Modern Medicine

- Core Applications in Orthopedic and Craniofacial Implants

- Advantages Over Traditional Mesh Fabrication Methods

- Why Titanium Reigns Supreme for Medical-Grade Mesh

- Step-by-Step Breakdown of Premold Titanium Mesh Production

- Rigorous Quality Assurance Protocols in Mesh Manufacturing

- FAQ

EN

EN

FR

FR

ES

ES

AR

AR