Introduction to Maxillofacial Mini Plates in Modern Surgery

The Critical Role of Mini Plates in Facial Fracture Repair

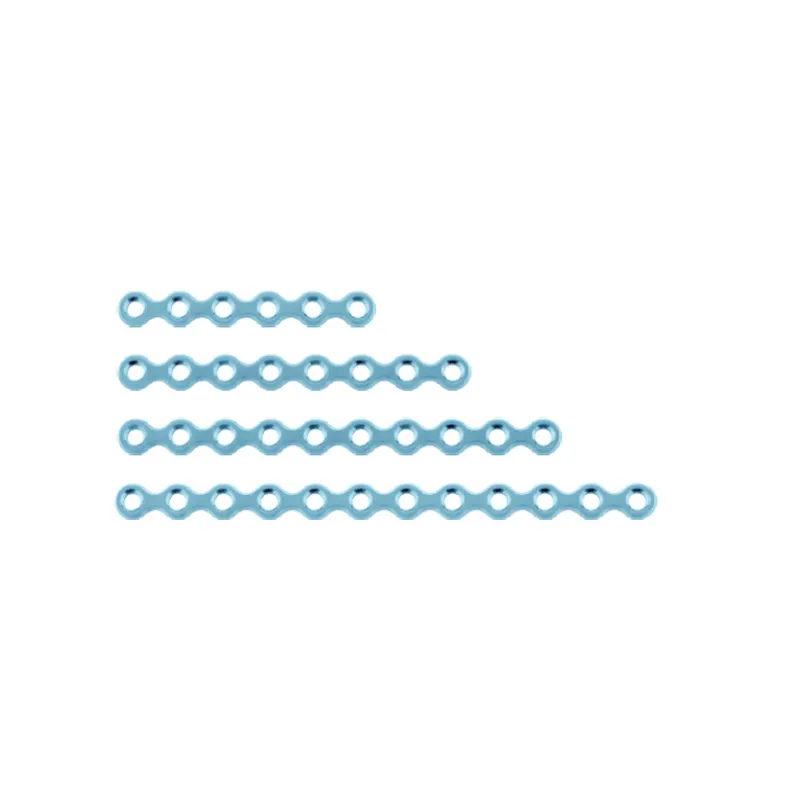

Maxillofacial mini plates are invaluable in the stabilization of facial fractures, playing a crucial role in modern surgery. Their lightweight and robust design ensures that the fractured facial structures are held securely, enhancing the alignment and promoting swifter recovery. In contrast to traditional approaches, which might have involved bulkier equipment, mini plates significantly reduce the burden on the facial area. This not only minimizes patient discomfort but also accelerates the healing process. Clinical studies have demonstrated that integrating these plates into surgical procedures can decrease overall surgery time and improve the precision of fracture alignment, making them a preferred choice for surgeons worldwide. The efficiency and effectiveness of mini plates underscore their pivotal role in facial fracture repair, aligning with contemporary needs in maxillofacial surgery.

Evolution from Traditional Fixation Methods

The evolution from traditional fixation methods to the use of maxillofacial mini plates marks a significant advancement in surgical techniques. Initially, surgeons relied on larger plates and screws, which often led to increased discomfort and prolonged recovery periods for patients. However, the emergence of mini plates has transformed surgical approaches, offering a more refined and patient-friendly option. This shift is not only a response to the complications associated with larger devices but also a testament to technological progress in the field. Historical data reveals a clear trend: as mini plate technology was embraced, post-operative complications decreased significantly. This innovation reflects the broader trend in medicine towards devices that improve patient outcomes while shortening recovery times, effectively contributing to the broader evolution of maxillofacial surgery.

Material Selection: Why Medical-Grade Titanium Dominates

Key Properties of Surgical Titanium Alloys

Surgical titanium alloys stand out primarily due to their excellent strength-to-weight ratio, which is crucial for the structural demands of surgical plates. These alloys balance the need for robust support without adding unnecessary weight to implants such as maxillofacial mini plates. Titanium's biocompatibility also makes it an ideal choice, minimizing adverse body reactions and ensuring patient safety. As such, titanium alloys have become the standard in medical-grade materials due to their superior performance. Clinical research consistently supports the fatigue resistance of titanium, further establishing its dominance over other metals used in surgical applications.

Comparative Analysis: Titanium vs. Alternative Materials

When comparing titanium to other materials, titanium's attributes remain compelling. While stainless steel has been traditionally used in medical implants, titanium offers distinct advantages like unmatched corrosion resistance and lower density. Emerging materials such as PEEK show potential, but studies reveal that titanium maintains superior performance under stress. A comparative analysis underscores titanium’s longevity, with many professionals considering it the benchmark for surgical material performance. This analysis confirms why the preference for titanium continues to dominate in the medical field, including applications such as maxillofacial mini plates.

Precision Manufacturing Techniques in Plate Production

CNC Machining for Microscopic Accuracy

Computer Numerical Control (CNC) machining is instrumental in producing maxillofacial mini plates with the precision needed for surgical success. Utilizing CNC technology allows manufacturers to adhere to exact specifications, critical in ensuring the functionality and safety of medical devices. This method reduces human error, standardizes quality, and enhances efficiency during mass production. Recent statistics indicate a significant boost in production efficiency when employing CNC machined processes as opposed to traditional manufacturing methods, making it an indispensable tool in the medical device industry.

Micro-Milling for Complex Geometries

Micro-milling is another pivotal technique in the production of mini plates, as it provides the ability to craft complex geometries required to fit unique anatomical structures. This precision allows for plates to better contour and stabilize on the target anatomy post-surgery, enhancing patient outcomes. Studies have shown that plates engineered using micro-milling techniques yield superior clinical results, confirming that increasingly detailed and shaped designs can be effectively managed with this technology, crucial for patient-specific or complex surgical needs.

Quality Control in Production Lines

In the production of surgical plates, rigorous quality control is vital to meet the stringent standards necessary for medical applications. Improving quality control processes, such as the implementation of automated inspection tools, ensures that each piece meets safety and efficacy criteria before reaching the operating room. Data supports that the integration of advanced quality control measures correlates with a marked decrease in product recalls and surgical complications, underscoring the importance of maintaining high standards throughout the production line.

Advanced Surface Treatments for Enhanced Performance

Anodization and Passivation Processes

Anodization and passivation are essential surface treatments that significantly boost the corrosion resistance of titanium plates—an imperative feature due to the humid conditions within the human body. These treatments enhance surface hardness, reducing wear and prolonging the device's lifespan in the patient's body. For instance, anodization involves creating a protective oxide layer on the titanium surface, which not only improves its aesthetic appearance but also increases longevity and functional durability. Benchmarked studies indicate a marked improvement in patient outcomes with anodized mini plates, highlighting their importance in maximizing performance and minimizing complications during surgical applications.

Ultrasonic Cleaning for Optimal Biocompatibility

Ultrasonic cleaning is an advanced technique employed to achieve optimal biocompatibility of implants, playing a crucial role in the successful integration of the implant with the surrounding bone. This method efficiently removes residues that may hinder osseointegration, thus fostering a stronger bond between the implant and the bone—a necessity for patient recovery and reduced post-operative complications. Research suggests that ultrasonic cleaning yields higher rates of successful implants compared to traditional cleaning methods due to its ability to effectively eliminate contaminants. The significance of biocompatibility cannot be overstated, as studies show decreased infection and complication rates after surgery when using implants cleaned with ultrasonic technology.

Design Innovations Driving Surgical Success

Anatomical Contouring for Bone Adaptation

Anatomical contouring has fundamentally transformed the design of maxillofacial mini plates to ensure better adaptation to the bone surface. By incorporating contouring, the plates now achieve a precise fit, significantly enhancing patient outcomes. Custom-fit plates are often crafted using advanced 3D modeling techniques that tailor the plate to the unique anatomy of a patient's bones. This customization is crucial for improving surgical stabilization and reducing recovery times, as it allows for more effective fixation and load distribution. Furthermore, statistical analyses underscore the efficacy of these anatomically contoured plates, revealing improved healing rates and patient satisfaction post-surgery. It's a testament to how tailored surgical solutions are paving the way for more efficient and successful interventions.

Low-Profile Engineering for Tissue Compatibility

The advent of low-profile engineering is another leap in maxillofacial surgery, prioritizing both patient comfort and treatment efficacy. These designs minimize the bulkiness of mini plates, thereby reducing the risk of irritating surrounding soft tissues—an innovation that translates to significantly better patient comfort. Despite their thin structures, these plates maintain strength and durability, proving that reduced dimensions need not compromise performance. In fact, reports consistently indicate a marked decrease in post-operative discomfort thanks to these low-profile designs. As a result, patients experience not only physical comfort but also accelerated healing, underscoring the necessity of such forward-thinking design advancements in surgical practice. Incorporating these innovations into standard practice demonstrates the evolving nature of maxillofacial surgery, where science, technology, and patient-centered care converge to deliver superior outcomes.

FAQ Section

What are maxillofacial mini plates?

Maxillofacial mini plates are small, lightweight plates used in the stabilization and alignment of facial fractures during surgery.

Why is titanium preferred for surgical plates?

Titanium is preferred due to its excellent strength-to-weight ratio, biocompatibility, corrosion resistance, and fatigue resistance.

How do CNC machining and micro-milling benefit plate production?

CNC machining and micro-milling provide the precision needed to manufacture plates with complex geometries, ensuring they fit anatomical structures accurately.

What role does ultrasonic cleaning play in enhancing surgical outcomes?

Ultrasonic cleaning removes residues that may hinder osseointegration, thereby fostering a stronger bond between the implant and bone, improving recovery rates.

EN

EN

FR

FR

ES

ES

AR

AR